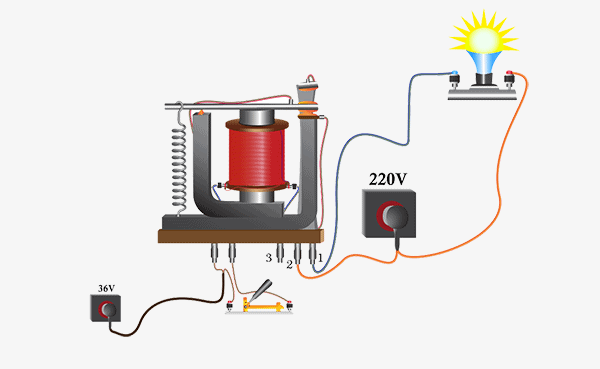

Air break circuit breaker uses atmospheric pressure in air as an air quenching medium. This type of circuit breaker employs a high resistance interruption principle.

The arc runners and chutes increase the arc length. Moreover, by cooling and splitting techniques arc resistance increases to such an extent that the voltage drop across the arc becomes more than the supply voltage. This will extinguish the arc at the current zero.

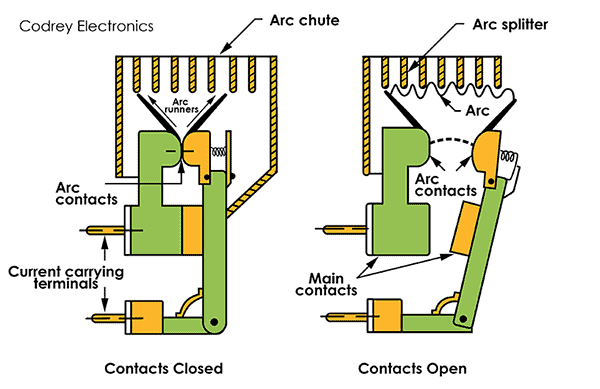

The breaker has two contacts: main contact and arc contact. The main contacts are silver plated and have low contact resistance. The current conduct when the mains contacts are in a closed position. The arcing contacts are made of copper alloy and they are heat resistant.

Working

When the breaker is in close condition, the current flows in the main contact. When the contacts are open, the main contact is separated first and the arcing contact remains closed.

Therefore, the current in the main contact moves to the arcing contact. Now the arcing contacts are separated and an arc is formed between them. Here, the high resistance is used for arc interruption.

The lengthening, splitting, and cooling the arc increases the resistance. The two chambers called arc runner (Arcing horns) and arc chutes increases the length of the arc. The arc moves along the arc runner and forced to move upwards into the arc chute. The arc is split in this way by arc splitters and thus it extinguishes.

Low and medium voltage systems use ACB in electric furnaces and in large motors. They are available in the range of 400V to 12kV.

Types of Air Circuit Breaker

There are three types of Air circuit breakers used in the low voltage switch gears and indoor medium voltage. They are:

- Plain Break Type or Cross-Blast ACB

- Magnetic Blowout Type Circuit Breaker

- Air Chute Circuit Breaker

Plain break type Air Break Circuit Breaker

Plain break type is the simplest form of air break circuit breaker. It is made in the shape of two horns. In this, the circuit breaker is fitted with a chamber surrounding the contact. The chamber is known as “arc chute”. The arc is made to drive in it.

The arc chute will help in achieving cooling. Arc chute is made from some refractory material. The inner walls of arc chute are shaped in such a way that arc is not only forced into proximity but will drive into the serpentine channel projected on arc chute wall. The arc chute is divided into several small compartments by using metallic separation plates.

Metallic separation plates are arc splitters and each of small compartments behaves like a mini-arc chute. The initial arc will split into a series of arcs this will make all arc voltages higher than system voltage. This type of circuit breaker is a good choice for low voltage applications.

Magnetic Blowout Type Circuit Breaker

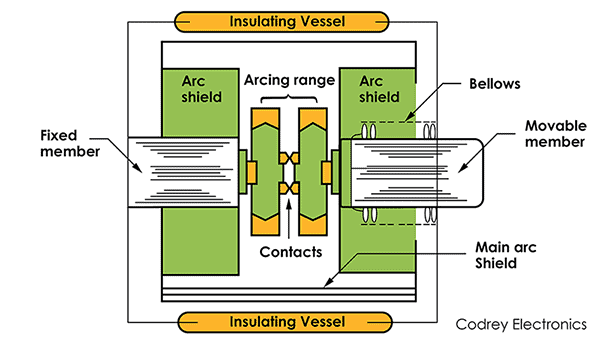

Magnetic blowout air circuit breakers provide magnetic control over the arc moment to make arc extinction within the devices. The arc extinction is controlled using the magnetic field provided by the current in blowout coils connected in series with the circuit being interrupted. These coils are called “blow out the coil“.

The magnetic field does not control and extinguish the arc made in the breaker, but it moves the arc into chutes where the arc is lengthened, cooled, and extinguished accordingly. These kinds of circuit breakers are used up to 11kV.

Air Chute Circuit Breaker

In the air chute circuit breaker, there are two types of contacts namely “main contact” and “auxiliary or arcing contacts”. The main contacts are made of copper and the silver plates having low resistance and conduct the current in a closed position.

Auxiliary or arcing contacts are made of a copper alloy as they are heat resistant and used to prevent from damaging the main contacts due to arcing and can be easily replaced when needed in case of wear and tear. During the circuit breaker operation, the arcing or auxiliary contacts are closed before and open after the main contacts of the circuit breaker.

Here are the advantages and disadvantages of the air circuit breaker.

Advantages:

- There is no risk of fire

- It washes away the arcing products and it prevents restriking

- Easy to operate

- Low maintenance

Disadvantages:

- Inefficiency at low current where the electromagnets are weak

- The chute itself is not necessarily less efficient in its lengthening and deionizing action than at high currents, but the arc movement into the chute tends to become slower, and high-speed interruption is not necessarily obtained.

Conclusion

In air break circuit breaker arc is extinguished in the air at atmospheric pressure. It is a preferable choice of circuit breaker because it has no risk of fire or explosion like in oil circuit breakers. It is used for high voltage applications for up to 15kV.