The vacuum circuit breaker (also known as vacuum interrupter or VCB) uses the arc quenching process in the vacuum as a switching medium.

The vacuum has the highest insulating strength. So, it has far superior arc quenching properties than any other medium. The degree of vacuum is in the range of 10^-7 to 10^-5 torr. It is suitable for medium-voltage power distribution ranging from 22kV to 66 kV.

Construction of Vacuum Circuit Breaker

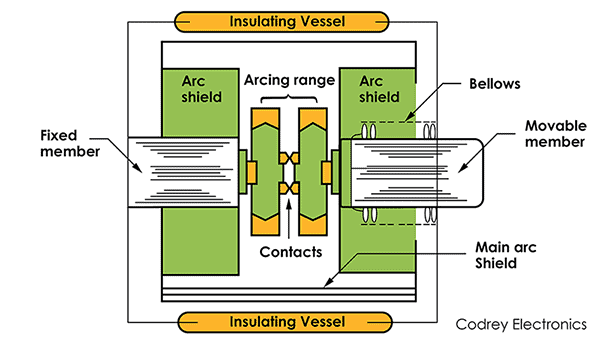

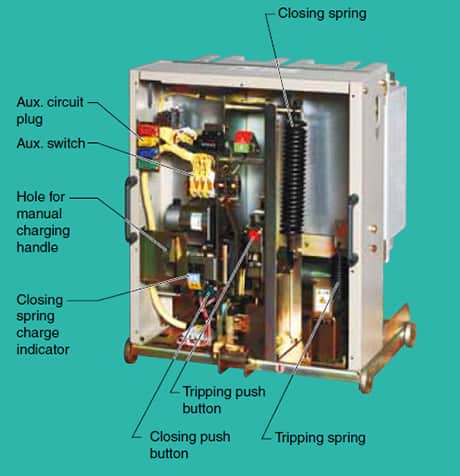

The below figure shows the vacuum circuit breaker parts and their construction.

The vacuum circuit breaker consists of fixed contact, moving contact and an arc shield mounted in a vacuum interrupter. The outer insulating body is made with glass and has a high vacuum capacity. The movable member is connected to the bellows.

The arc shield prevents the deterioration of the internal dielectric strength by preventing metallic vapors from falling on the inside surface of the outer insulating body. This allows reducing the chopping current up to 3.5 amperes. To reduce the leakage permanently, the tight sealing of the chamber is done.

The contacts use a large stem with disc shape faces. To dissipate heat for large overload current during arcing, contact materials like copper alloy is used.

Working of Vacuum Circuit Breaker

The working principle of vacuum circuit breaker (VCB) is the arc quenching using vacuum interrupters. The operation of VCB depends on the stored-energy mechanism using closing spring. The spring system reduces the closing operating current.

The charging of closing spring is done electrically or manually. For this VCBs, the closing spring recharges automatically after the operation of the circuit. The tripping push button activates the tripping spring immediately after detecting high voltage and breaks the circuit.

The auxiliary switch contacts and primary contacts are separate. The auxiliary contacts provide a trigger signal for the external equipment (burglar alarm and fire alarm circuits) to initiate shut down or alert the user that the breaker has tripped.

When the VCB contacts are separated, an arc is formed between the contacts. Ionization occurs because of the high temperature due to the arc formation. Space is filled with a vapor of positive ions due to ionization and discharges from the contact material.

The arc extinguishes quickly because of the metallic vapors, ions produced during arc diffuses in a short period of time. This is known as a diffuse mode.

Now Let’s discuss the vacuum circuit breaker advantages and disadvantages.

Advantages :

- Compact and reliable

- Longer life

- No risk of fire

- Small switching stroke

- High dielectric strength

- Easy maintenance

- Arc extinction is very fast

Disadvantages:

- The cost of VCB will increase if the voltage exceeds 38kV

- Loss of vacuum due to failure makes the entire current interruption useless

Applications of VCB

The uses of the vacuum circuit breaker are:

- High voltage circuits

- Used in substations and generators

- Interrupts the double earth faults and out of phase currents

- Applications that require high switching sequences use VCBs

- Railway applications use this circuit breaker for traction current and electric supply switching.

- To switch motor drives.

Conclusion

Vacuum circuit breakers (VCBs) are reliable for the current interruption in medium voltage applications because it requires minimum maintenance. The voltage range of the vacuum circuit interrupter is 11 kilovolts to 33 Kilo volts.

They must make and break all the current within the range of voltage ratings. They break from small capacitive and inductive current to high short circuit currents.

But it is not suitable for high voltage applications as it increases the cost and becomes uneconomical. Unlike oil or air circuit breakers, VCB avoids the risk of fire or explosion.