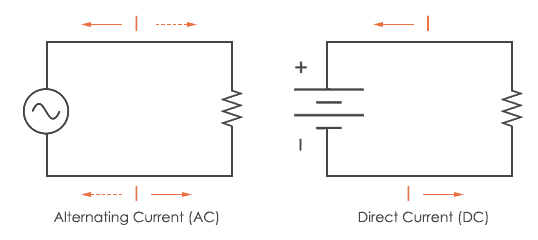

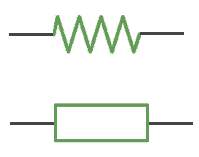

Resistors can be seen in almost all electronic circuits. There are many types of resistors and they can be divided into two groups namely fixed resistor and adjustable resistor (variable resistor). The main function of the resistor is to resist the flow of electric current and regulate the flow of electrons. This is done by the material from which they are composed. They are mainly categorized on the basis of their applications, temperature coefficient, tolerance, size, power, reliability, voltage, etc.

Fixed value Resistors: Fixed resistors are the type of resistors which offers a fixed amount of resistance in the circuit. A fixed resistor cannot be changed as it is set at a specific value.

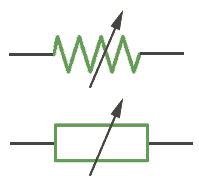

Variable Resistors: Variable resistors are the type of resistors in which the value of resistance is not fixed. We can change the value of resistance in variable resistors.

Construction

Fixed value resistors are the resistors which have fixed value and their value does not change on change of value or current. These fixed value resistors can further be divided according to their construction into carbon composition resistors, carbon film resistors, metal oxide film and wire-wound resistors.

Carbon composition Resistor

Carbon composition resistors were used for over 100 years but are rarely used today. They are large as compared to our general resistors. Carbon composition resistors are made by mixing carbon granules with the help of binder which is a binding agent and then converted into a small rod. The biggest advantage of these resistors is that they can withstand a high level of energy pulses. Although they have many disadvantages like big size, noise, high negative temperature coefficient, and instability. Due to these disadvantages, this type of resistors are not used today or rarely used. They can be used in RF loads.

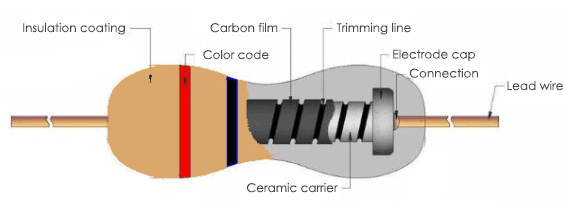

Carbon film Resistor

Carbon film resistors have the carbon film on the ceramic former and they are covered with insulation coating material like epoxy (for protection). This type of resistor is not used today as superior resistor technologies are available in lower cost. Carbon film resistors are formed by cracking of hydrocarbons on a ceramic former which makes carbon film on it. After that connection are added and a helix cut is given to adjust the value of resistance. Helix cut is the smooth curve on the surface; this makes these resistors inductive and makes them usable in RF applications. The helix curve is indicated as a trimming line. An electrode cap is connected to the lead wire for closing the carbon film.

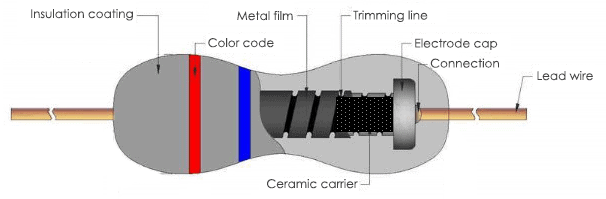

Metal oxide film Resistor

This type of resistor is widely used today. They are far better than the carbon film resistors. Here, metal oxides (metal film) like tin oxide are deposited on the ceramic carrier. Then resistance is adjusted by using the trimming line. The resistance varies depending upon the thickness of deposition and after that by helix curve. After that outer covering is covered by an epoxy protection layer (insulation coating). These resistors have low noise and can be supplied to much more close tolerance and thus make them far superior from carbon film resistors. This type of resistors is used in almost all applications now.

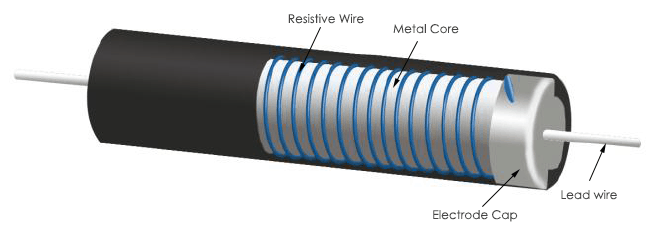

Wire Wound Resistor

Wire wound resistors are made by winding metalcore (wire) on a ceramic former. The ceramic former is used in costly wire wound resistor. This gives more resistance than general. After winding wire, they are covered with vitreous or silicon enamel. The whole material is tightened with electrode cap. This type of resistor is used for high power applications.

Variable Resistors

Variable resistors are of many types. They are mainly categorized on the basis of how the resistance value of adjusted. Here, resistance value depends on the operator or other natural sources. They are mainly classified as Potentiometer (abbreviated as Pot), Light dependent resistor, thermistors.

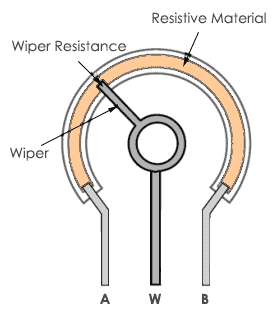

Potentiometer

Potentiometers are the type of variable resistors. In potentiometer, there are three terminals and a rotating shaft which when rotated changes the value of resistance.

The potentiometer has a resistive track which is made up of resistive material. When the wiper is rotated, the amount of resistance changes and thus it is reflected in the second terminal of the potentiometer. This type of resistors is used in applications like fan regulators, power supplies, etc.

Variable potentiometers are available in a variety of different mechanical variations allowing for easy adjustment to control a voltage, current, or the biasing and gain control of a circuit to obtain a zero condition. Some of them are slider potentiometer, Presets, trimmers, and rheostats.

Slider potentiometers are potentiometers in which resistance value is changed by a slider which is a linear force. Presets or trimmers are miniature versions of potentiometers. They are used in a circuit where we have to just fix them and forget. A rheostat is a variable resistor which is used to control current. They are able to vary the resistance in a circuit without interruption. The construction is very similar to the construction of potentiometers but they have only two terminals.

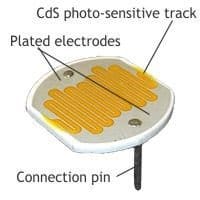

Light Dependent Resistor (LDR)

Light Dependent Resistors are shortly known as LDRs. LDR is a type of variable resistor in which the value of resistance changes with the light intensity that falls on it. Light-dependent resistors have a photosensitive track made up of cadmium and silicon which is sensitive towards the light. It has a resistance which changes its value according to the wavelength of light incident on LDR. They are also known as photoresistors. They are used in light-sensitive applications like in smart street lights, camera, etc.

Thermistors

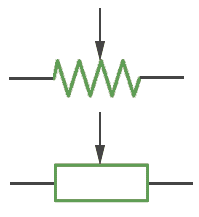

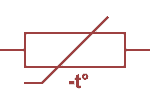

The thermistor is an electrical resistor whose resistance is greatly reduced by heating, used for measurement and control. Also, there are two types of thermistors:

NTC (Negative Temperature Coefficient) thermistor: In NTC thermistor, resistance decreases with increase in temperature. The symbol of the NTC thermistor has -t because it has a negative temperature coefficient.

The sensitivity of NTC thermistors is far better than silicon temperature sensors and RTDs. There are two ways to change the temperature of the NTC thermistor. First is by changing atmosphere temperature and the other is by increasing current in the thermistor. By increasing the current, there will be a heating effect in the resistor and thus it will change its resistance by its own heat. This is called the self-heating effect.

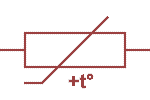

PTC (Positive Temperature Coefficient) thermistor: In PTC thermistor, resistance increases with increase in temperature. PTC means thermistor. Symbol of PTC thermistor has +t because it has a positive temperature coefficient.

PTC thermistors are used widely as self-regulatory heaters. When the high amount of current is passed through it, more heat is evolved and thus the resistance of thermistor increases dramatically. Thus they are often used in temperature-dependent time delay circuits. PTC thermistors are also used for measuring temperature but in this process, it consumes the very negligible amount of current which makes it very useful for this application.

The temperature coefficient is the change factor of resistance by the change of temperature by one degree Celsius. Every conductor has a temperature coefficient. Some have negative and some have positive. Thermistors are specially designed to change their resistance with a change in temperature. Generally, normal resistors are prepared using alloys and resistors that has temperature coefficient nearer to zero so they do not change their value more by the change in temperature.

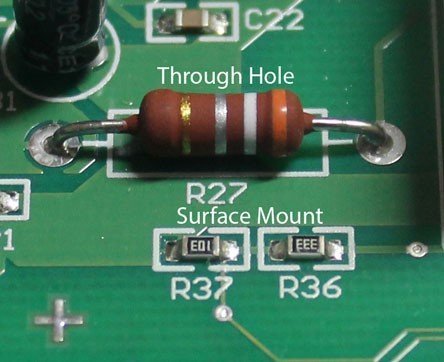

They are used in resistance thermometers and other temperature controlled applications. And finally, they are categorized as through hole resistors and surface mount resistors.

Through-hole Resistor: Through-hole resistors come with long, pliable leads which can be stuck into a breadboard or hand-soldered into a prototyping board or printed circuit board (PCB).

Surface mount Resistor: SMD resistors are rectangular in shape. Chip resistors have metalized areas at either end of the body and this enables them to make contact with the printed circuit board through the solder.

We see a large number of resistors in a circuit. They are the main part of the current controlling systems. Although we see different types of them like in fan regulators we find rotary potentiometer and general metal oxide film resistors while in mobile phones we find SMD resistors while in RF device, we find large resistors; in high power applications like in inverters wire wound resistors can be seen. Thus, there are hundreds and thousands of types of resistors since they are made. Some are still in use and some are outdated. They are used according to their applications.