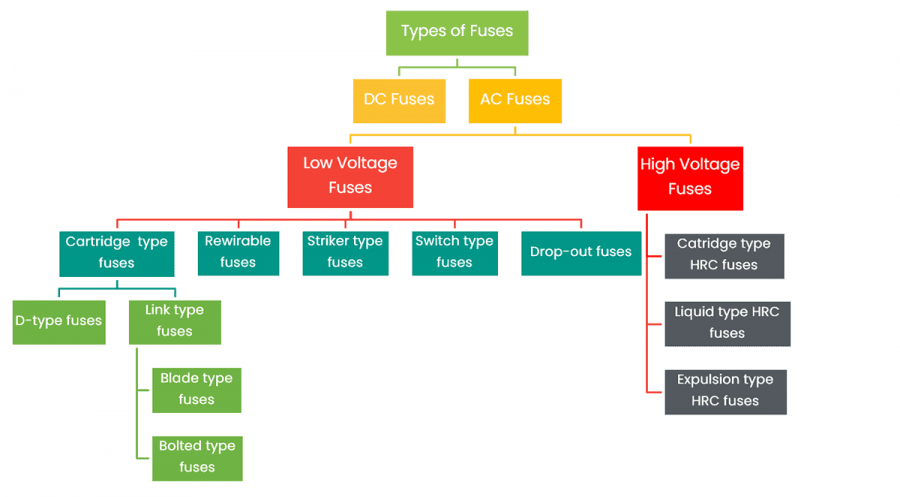

Many types of fuses are there that interrupt an over-current and breaks the circuit by melting the fuse element. They are mainly divided into two types, AC fuse, and DC fuse. Furthermore, fuses are classified into different types depending on voltage and construction. They are:

Types of Fuses

-

DC Fuses

DC fuses produce an arc that are difficult to stop than AC arcs because there are no zero current flows in the circuit. For reducing the DC fuse arcing the electrodes are placed at more distance due to which the size of the fuse increases as compared to AC fuse.

-

AC Fuses

In AC circuits, the arc extinguishes easily when compared to DC circuits. Because the frequency of the AC fuses changes its amplitude from 0º to 60º in every one second. AC fuse is further divided into two categories. They are low voltage fuses and high voltage fuses.

2.1 Low Voltage Fuse

Low voltage fuses are very common in electrical systems and they come in different shapes and designs. Low voltage fuses have a voltage rating of less than or equal to 1,500V.

2.1.1 Cartridge Type Fuse (Totally Enclosed Type)

Cartridge fuse consists of the heat-resisting ceramic body enclosed by a metal cap at both ends. The filling material such as chalk, plaster of Paris, quartz or marble dust surrounds the body space which acts as an arc quenching and cooling medium. Often, they are widely used in industries, agricultural areas and residential purposes such as fuse panels, air conditioning, pumps, and home appliances

These types of fuses are classified into D-type and Link-type fuses.

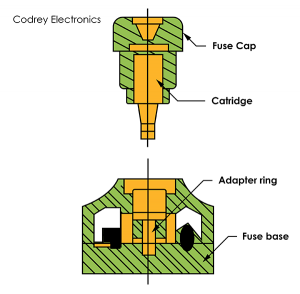

2.1.1.1 D-type Fuse

It consists of an adapter ring, cartridge, base, and cap. The fuse base is connected to the fuse cap and the cartridge is kept inside the fuse cap through the adapter ring. The circuit gets completed when the tip of the cartridge makes contact with the conductor.

2.1.1.2 Link-type Fuse

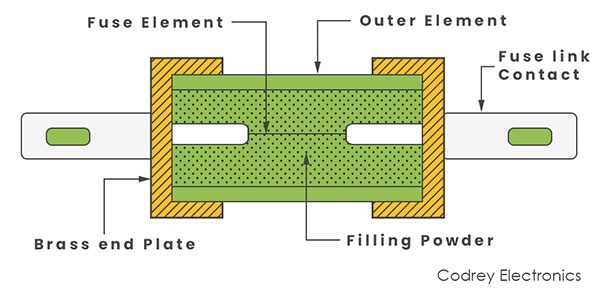

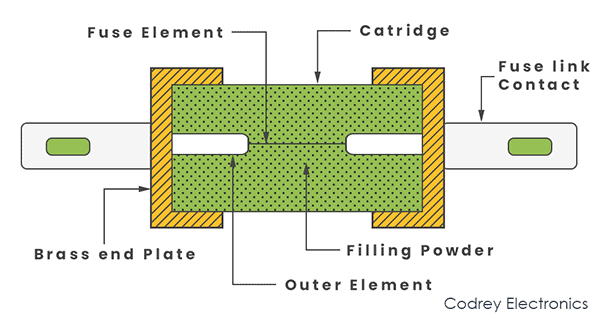

Link-type cartridge fuses are also known as High Rupturing Capacity fuses (HRC). HRC fuse has a high breaking capacity. It has two metal ends on both sides. The Filling of the fuse with powdered pure quartz acts as an arc extinguishing agent. The fuse element uses silver or copper for its construction.

The fuse element carries the short circuit current for a long period of time. During this time, an uncertain fault will melt and open the circuit. The chemical reaction between a silver vapor and the filling powder forms a high resistance which helps in quenching the arc.

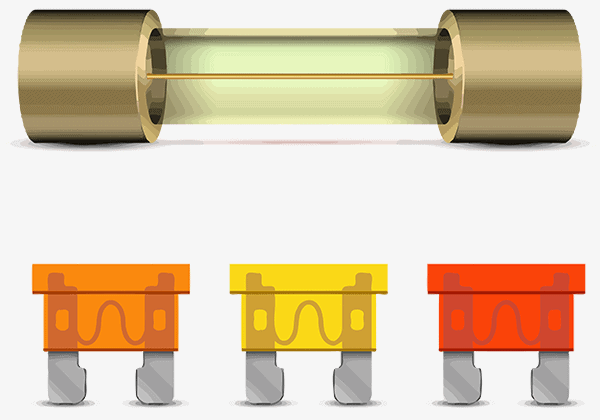

The breaking capacity of the fuse is increased by using two or more silver wire in parallel. This type of fuse is very reliable and divided into two types: Blade type fuses and Bolt down type fuses.

The Blade fuse are also known as spade or plug-in fuse. Automotive OEMs use this fuse for vehicle circuit protection and withstand high temperatures. Whereas, Bolt down fuse are special-purpose ones suitable for diesel vehicles and not appropriate for automotive trucks.

2.1.2 Rewireable Fuse

Re-wirable fuse is also known as a kit-kat fuse. It is a simple and cheapest form of a fuse. This fuse is suitable for domestic wiring for e.g in houses. Moreover, when the fuse blows out, it is easy to replace and reuse.

It consists of a fuse base and a fuse carrier. The construction of fuse element in the fuse carrier uses tinned copper, lead or aluminium and porcelain for the base.

The base has two terminals for incoming and outgoing supply. When a fault occurs, the fuse element blows out and interrupt the circuit. The blown-out fuse can be replaced by a new one. The main advantage of this type of fuse is, it is rewireable but the disadvantage is less reliable.

2.1.3 Striker Fuse

This type of fuse has a mechanical indicator or striker pin that protrudes through the fuse cap upon operation of the fuse. This provides visual identification of a blown fuse and acts as a trigger for external devices. It can be used for short circuit protection of medium voltage motors.

2.1.4 Dropout Fuse

Drop out fuse is an expulsion type fuse to protect the transformers. When the fuse element melts, it falls due to gravity, hence providing additional isolation.

2.1.5 Switch Fuse

Switch fuse is used for low and medium voltages circuit. They can safely break depending upon rating currents of the order of 3 times the load current.

2.2 High Voltage Fuse

Transformers and Power systems use High voltage fuses. The fuse element uses material such as copper, silver or tin. The rating voltage for high voltage fuse is above 1500V and upto 138000V. They are classified into three types: Cartridge type HRC fuse, Liquid type HRC fuse, Expulsion type HRC fuse.

2.2.1 Cartridge Type HV HRC Fuse

This cartridge fuse is similar to low voltage HRC fuse with some extra features. The fuse wounds in the shape of a helix or use two fuse elements in parallel to prevent the corona effect at the higher voltages.

One of the fuse element has low resistance and the other has high resistance. Therefore, a low resistance wire carries the normal current which blows out and reduces the short circuit current during a fault condition.

HV HRC fuses are available with a rating of 33kV with a rupturing capacity of 8700A.

2.2.2 Liquid Type HV HRC Fuse

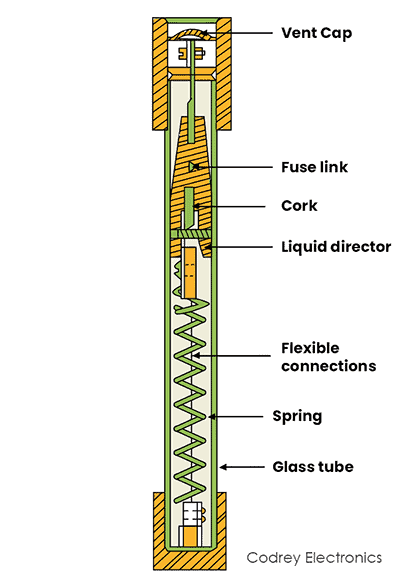

A liquid fuse (for high currents) consists of a glass tube filled with carbon tetrachloride and sealed with brass caps at both ends. The fuse wire covers sealing at one end and fixing by strong phosphor bronze spiral spring at another end of the glass tube. The liquid acts as an arc extinguishing medium.

The fuse blows out when the current exceeds the maximum limit. Liquid type HRC fuse protects transformer and circuit breakers. They withstand current upto 100A on systems up to 132kV.

2.2.3 Expulsion Type HV HRC fuse

This type of fuse is an escapable fuse in which the expulsion effect of the gases produced by internal arcing results in current interruption. The fuse link chamber contains boric acid. Therefore, an internal arcing helps in the protection of feeders and transformers.

Fuse Applications

Some of the applications of fuse for industrial applications are:

- Used to protect transformers, motors and power system from over-current conditions

- In feeders, power transformers, and solar circuits

- Electrical appliances and house distribution boards use fuse for domestic purposes.

- Used in automotive cars, electric vehicles, racing cars, rails

- Fuses are present in laptops, hard disk drives, printers/scanners, and electronic devices.

- Used in gaming systems and smartphone

Conclusion

There are different types of fuses in the market and each fuse has its advantage and use. They are self-acting brake appliances for the protection of loads. Moreover, they are present in cable wires and motors for protecting short circuits.

Thank you for helping me out with my study

Thanks 👍 alot,, the material was helpful

I have always wondered how they deal with fuses at extremely high voltages. Now I know. Very informative, well written and interesting article!