Moving iron Instrument or Moving iron meter is used to measure the current and voltage of AC and DC. They are non-directional. The working principle depends upon the movement of iron attracted by the magnetic field towards it and repulsion between them. The magnetic field is produced by the current in the coil.

This instrument can be used as an ammeter, voltmeter, and wattmeter. The coil has less number of turns if the instrument is ammeter and more turns if the instrument is a voltmeter. The moving iron type supports both AC and DC.

To use this instrument as ammeter, connect the circuit in series and the coil must have fewer turns of thick wire which shows less resistance. To use it as a voltmeter, connect the circuit in parallel and the coil has a high impedance and a large number of turns.

The construction of moving iron instrument is divided into two types :

- Attraction iron meter (Uses single iron)

- Repulsion type moving iron meter(Uses double iron)

Attraction Type

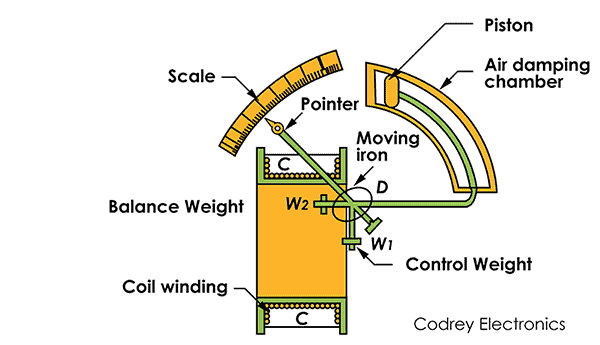

Attraction type moving iron meter consists of a moving system which has soft iron. The current is passed through a coil placed near it. The moving iron is attracted to the coil which produces a magnetic field when a current flow through the coil.

It consists of a fixed coil wounded by a copper wire. Soft iron is free to move on the spindle and a pointer is also attached to the spindle.

How Attraction type Iron Meter Works?

The working of the Attraction type iron meter is When the current flows through the coil, the moving iron attracted to the coil which causes the pointer to move. The pointer will come to zero position where deflecting torque is equal to the controlling torque.

When the current in the coil is changed, the direction of the magnetic field also changed and the moving iron will get magnetize in such a way that it is pulled inwards. Hence these types of instruments can be used for both AC and DC currents.

Here the air friction damping is provided by the air chamber because the magnets can affect the deflection of the pointer and the readings can be changed. Controlling torque is provided by the spring.

Repulsion Type (double Iron)

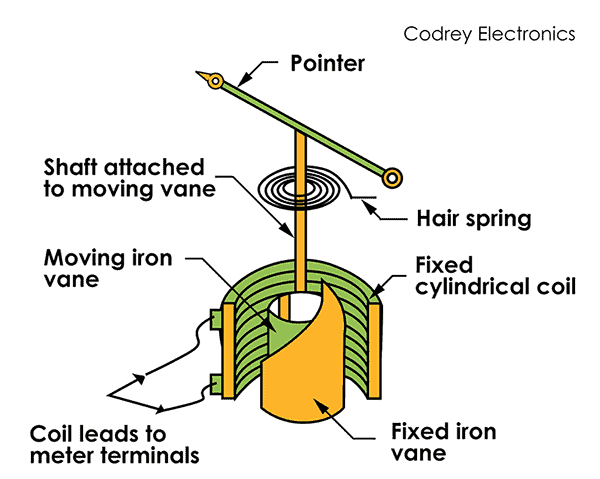

The repulsion type moving iron instrument consists of soft iron in the form of the vane as the moving element of the meter. It also has a fixed iron vane. A shaft is attached to the moving iron. A cylindrical stationary coil is used to produce the magnetic field when there is a flow of current through it. A pointer is fixed on the shaft which gets deflected shows the reading on a non-uniform scale.

The strength of the magnetic field increases or decreases with the magnitude of the current flows through it.

Moving Iron Instrument Working

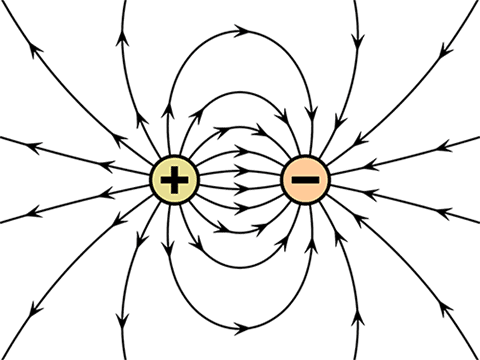

The moving iron and fixed iron magnetize with the same polarity due to which the two irons repel each other (when the same type of magnetic materials is placed in a magnetic field they will get magnetized uniformly and they repel each other). Because of their repulsive force, the coil starts moving away from the fixed iron.

The controlling torque is exerted by the spiral spring made of phosphor bronze which is connected to the shaft. An air chamber is provided for air friction damping because the magnets can affect the deflection of the pointer and affect the reading. The deflection torque makes the pointer to move away from the zero position.

Torque – Weight Ratio

Torque is a force that makes an object move and weight is a force applied on the object by gravity. If a pointer in the meter has less weight, it will have a high torque-weight ratio. Even for a small deflection in the meter, the pointer will start moving and it shows measured value.

Here are some advantages and disadvantages of moving iron instruments.

Advantages:

- This type of instrument is simple and cheap in construction.

- It is non-directional hence can be used in both AC and DC circuits.

- Because of the current-carrying part is stationary and has lighter moving parts, the torque weight ratio is high.

- Due to the high torque weight ratio, the frictional error is very less.

Disadvantages:

- Accuracy is less because of the instrument is non-directional.

- It cannot be calibrated with a high degree of precision for DC on account of the effect of hysteresis in the iron vanes.

- High power consumption.

direct to the point!!!!!